Like most solid partnerships, it started with a friend of a friend. They understood what both Blue and The Canton Cutler were about and knew we'd get on well.

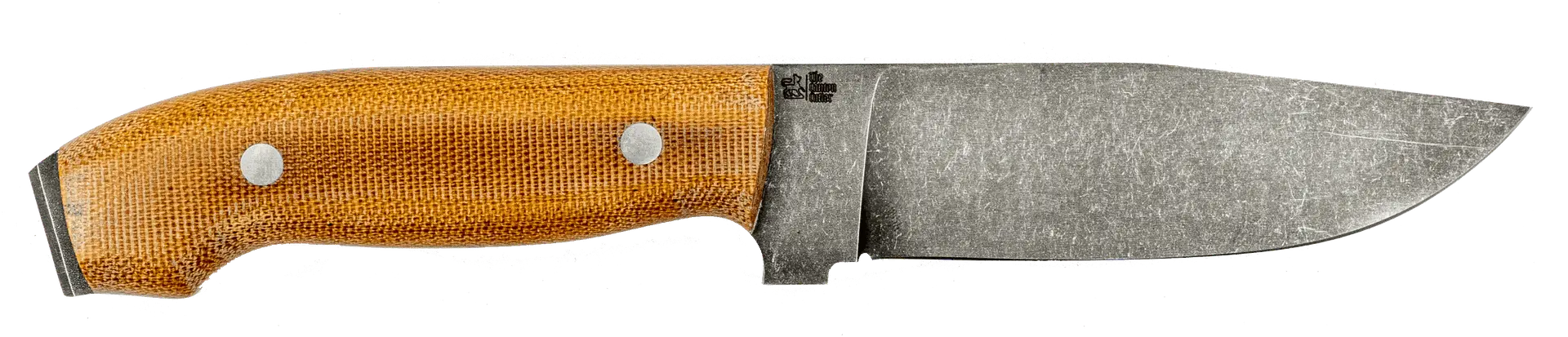

Image shows the Butch Bach, a knife with a past.

Story so far:

5 knives tested, 17 knives in stock, 36 WhatsApp videos exchanged, 4 designs in development (including my favourite, 'The Key'), 2 Moments of Reflection, plus sharpening & stropping lessons along the way.

We chose to work with Jake because he's an unusual knife maker — he makes high-end tools for actual use, not display or showing them off to mates. His custom knives are built with purpose, shaped by experience, designed to work rather than just look pretty.

No mirror finishes or delicate show pieces, just proper tools and a custom knife that'll last. That gels with how we see things and use EDC's.

Three of our team are into knives (The other one sees them as disposable and spends accordingly). For us though, we've all spent too much on blades that end up on shelves or in blocks, too good to use in case they get marked or need sharpening. So we grab the cheap ones instead, or the old workhorses that can take a beating. The ones we can run through a pull-through sharpener because who has time for the Tormek, although we have two in the workshop?

It leaves us feeling dissatisfied.

Stephen mentioned he only played with his Benchmade and two nice Boker knives at his desk. One of them opened an envelope in May 2023.

Stephen's daily knives:

Jake's bespoke knives solve that problem. They're well-made without being precious, striking without being fragile. They are designed and built to be carried and used properly. That's why we're working together.

Each knife features:

Lifetime guarantee - free resharpening and servicing for life (yearly if required)

- Stropping leather & compound to keep your knife in good condition with video tutorials

- Tough Sandvik 14C28N stainless steel with a full flat grind for easy field sharpening

- Durable Micarta scales secured with marine-grade Corby bolts

- Sandblasted, etched and stonewashed finish that improves with age and allows for us to bring it back looking good as new after most mishaps

- A quality leather sheath with a 20 year guarantee

Let's hear from Jake and his knife maker philosophy.

(Click HERE for Jake's story)

Steel choice

Nearly all my knives use Sandvik 14C28N stainless steel. It's the best compromise I've found, and all knife steels are compromises. Damascus looks nice but function suffers. Edge retention and easy sharpening pull in opposite directions — those fancy powder steels hold an edge forever but are a nightmare to sharpen in the field. They're also expensive, and tools need to be used.

True stainless won't harden. Carbon steel is excellent but rusts. Sandvik 14C28N is tough, holds a decent edge, and resists corrosion. Dr Larrin Thomas (probably the only knife steel metallurgy PhD around) says it "has managed to strike a uniquely well-balanced profile." I haven't studied metallurgy myself, but I've read his book so you don't have to.

Construction

I use Corby bolts to fix handle scales to the tang — expensive but worth it. Most knife makers use pins and epoxy, but epoxy eventually fails and the scales fall off. Corby bolts give a mechanical connection that lasts. It's one reason I can offer a lifetime guarantee with free servicing.

The scales and tang get drilled to precise tolerances, bolts go in with marine epoxy, then everything's clamped under pressure and ground flush.

My preferred handle material is Micarta — layers of linen or canvas soaked in epoxy and heated. It's waterproof, feels natural in the hand, and looks good. Best handle material there is.

For the grind, I'm not a fan of the scandi grind that's popular with some brands. I'm a decent knife maker, but I can't keep a good edge on scandi-ground blades. A full flat grind with secondary bevel is more versatile — easier to sharpen anywhere and useful for more than just wood carving.

Surface finish

My bespoke finish is sandblasted, etched and stonewashed. It's the most durable surface you can put on a cutting tool. Cerakote looks good until you actually use the knife. DLC coating eventually wears through. Satin finishes can't be redone once the scales are fitted.

One of the best parts of offering free servicing is when a knife comes back from somewhere hot and sandy, properly battered. I tape up the scales, re-blast, re-etch and stonewash it, and it goes back out looking like new. That's why people can actually use these custom knives without worrying.

Principles

I stick to four things and do them well: fit, finish, form and function.

Fit — scales, bolts, guard — no gaps or rough transitions.

Finish — consistent and clean throughout.

Form — simple lines, good flow from handle to blade, comfortable in the hand for any job.

Function — this is the hard bit. The knife has to be genuinely useful.

I'm trying to make something that belongs on every belt, in every pocket, in every kitchen.

Blue Fieldsports Partners with The Canton Cutler